202 Stainless Steel Coil

Classification :

PRODUCT DETAILS

Keywords: Lingsen Metal

202 Stainless Steel Coil Description

202 stainless steel is an austenitic chromium-nickel-manganese alloy. It has high ductility, good corrosion resistance and excellent toughness in both high and low temperature environments. 202 stainless steel is one of the most widely used 200 series stainless steel. 202 stainless steel, the austenitic structure is stabilized by the addition of nickel and manganese, thereby preventing the formation of harmful phases, such as sigma phase or chromium carbide. The high nickel content also improves the corrosion and oxidation resistance of the steel at high temperatures.

Product Parameters

Product Name | 202 Stainless Steel Coil |

Type | Steel Coil |

Thickness | 2.5mm-10.0mm |

Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

Width | 610mm-2000mm |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

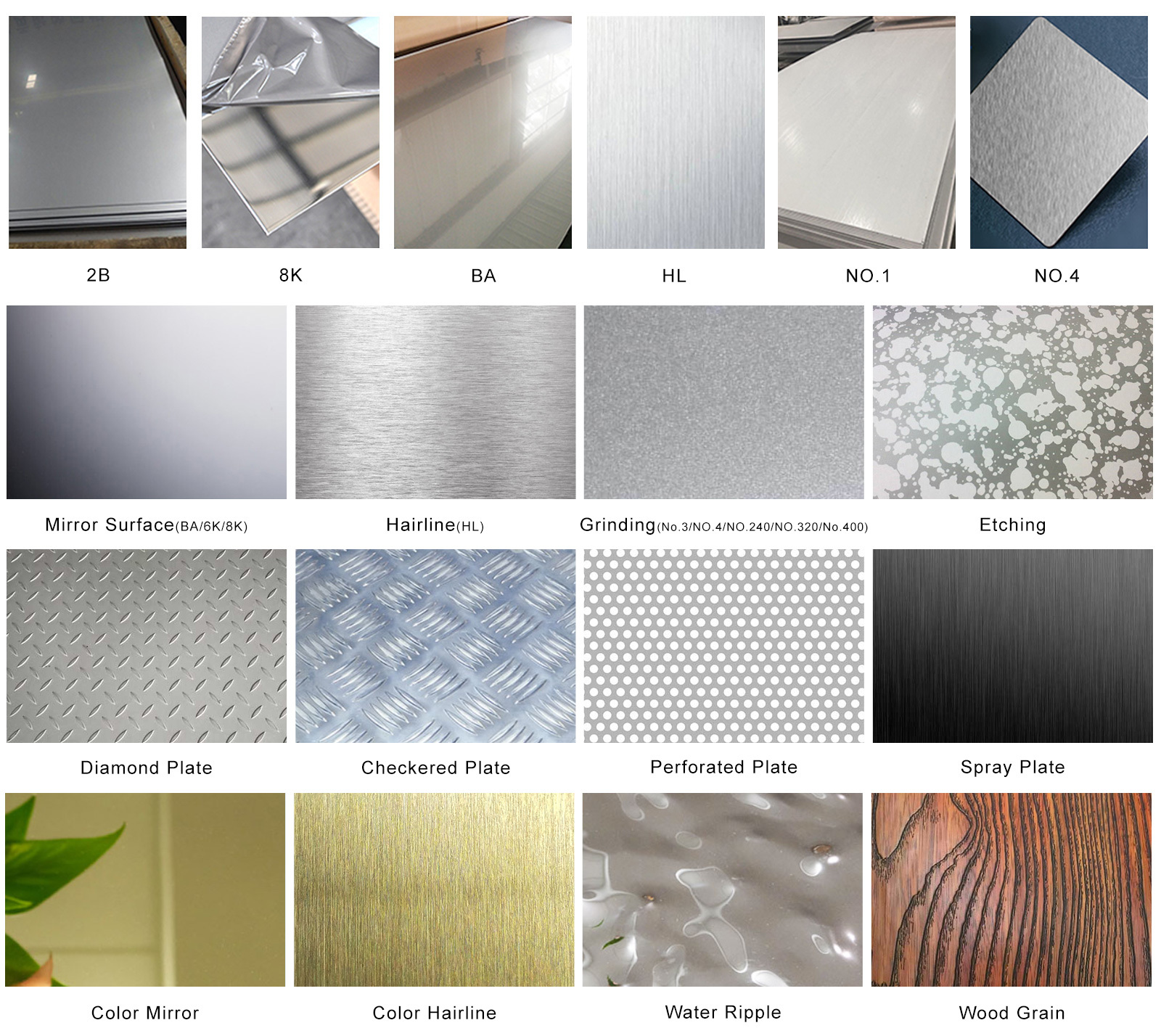

Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

Certificate | ISO, SGS, BV, etc. |

Production Technology | Hot Rolling, Cold Rolling |

Edge Processing | Edging, Trimming |

Chemical Composition

C | Si | Mn | Cr | Ni | S | P |

≤ 0.15 | ≤1.0 | 7.5~10.0 | 17.00~19.00 | 4.00~6.00 | ≤ 0.03 | ≤ 0.06 |

Mechanical Properties

Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

≥ 520 | ≥ 275 | ≥40-50 | ≤207HB;≤ 95 HRB;≤218HV |

Physical Performance

Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(μohm.in) |

7.93 | 203 | 17.5 | 16.3 | 22 |

Surface Selection

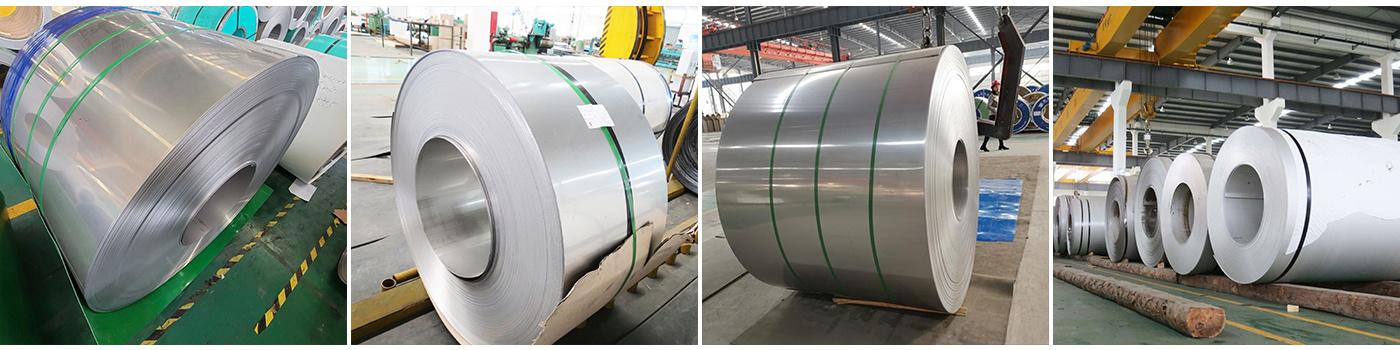

Packing and delivery

The main export products include steel products such as steel plates/coils/tubes/rods. The management has been engaged in the steel industry for more than 20 years, the management team is experienced and has established solid business relationships with customers and factories. Lingyue's annual sales volume exceeds 10 million tons, and it provides customized processing services for a variety of products.

CUSTOMER VISIT

The products are exported to more than 100 countries and regions around the world, including Europe, America, and Asia, and are well received by customers at home and abroad.

PARTNER

FACTORY WORKSHOP

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

APPLICATION AREAS

FAQ

Will you can accept the customized and OEM products?

A:Yes,we can do the production based on your drawings and with your logo,also because we have very strong design and development team,so the feedback is very good for customized product.

What is your payment terms?

A:Commonly two payment term for new customers (1)30%T/T as deposit,70% balance against B/L copy. (2)100% Irrevocable L/C at sight. If you need other terms, please feel free to contact us too, we will try our best.

How about the samples? Is it free to extra fees?

A:Samples are free, you need to pay for shipping.

How long is your delivery time?

A:Our daily inventory is more than 8000 tons, so far common products size,just need 5 days from stocks; if the special size from new production, delivery 7-15 days.

How to control and guarantee your shipment quality?

A:(1)All our factories are ISO 9001 certified facility; (2)World famous origin mills as TISCO, Bao steel; (3)Ex factory inspection by our own laboratory; (4)SGS/BV Third party inspection before delivery.

RELATED PRODUCTS

GET A FREE QUOTE